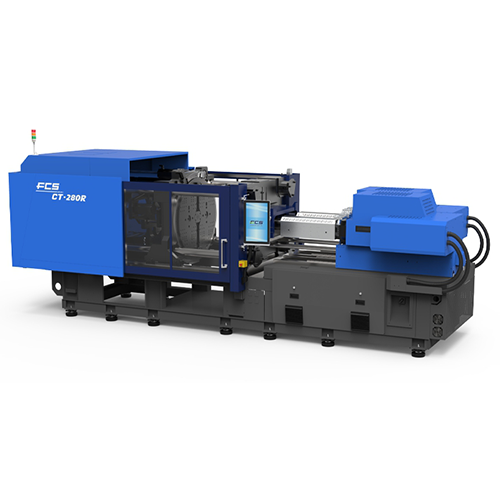

All-Electric Two-Component Injection Molding Machine (CT-R series)

Categories : Electrical Injection Molding Machines

It is All-Electric Two-Component injection molding equipment. It is suitable for two-component and multi-component products, including electronic parts, medical appliance, cosmetic containers, etc.

Rotary Shaft Two-Component Injection Molding Machine (FB-T Series)

Categories : Horizontal Injection Molding Machines

The rotary shaft two-component injection molding equipment, which is suitable for two-component products covering the penetration, including tool handles, buttons, handles and other products.

Large Horizontal Rotary Table Two-Component Injection Molding Machine (HB-R Series)

Categories : Horizontal Injection Molding Machines

It is a large injection molding machine, which is suitable for large-scale home appliances and panels, automotive skylights, lights,

Rotary Table Two-Component Injection Molding Machine (FB-R Series)

Categories : Horizontal Injection Molding Machines

It is rotary table two-component injection molding equipment. It is suitable for two-component and multi-component products, including automotive lamp housing, livelihood supplies, etc. FCS

Rotary Table / Separated Injection Multi-color Plastic Injection Molding Machines. Co-injection Multi-color Plastic Injection Molding Machines - TWR/TXIIR SERIES

Categories : Horizontal Injection Molding Machines

Increase The Flexibility Of Product Design : Molding process can minimize the use of internal space simultaneously. In addition, it can have different applications to increase the flexibility and variations of product design.The button part is designed in a dual-material method, it can be completed simultaneously during molding, reducing the assembly processes and achieving waterproof effects. Reducing Processes To Keep Costs Down: Can be combined with two parts of different materials or colors at the same time, reducing the need for secondary processing. Embellish the Appearance: With a variety of Colors and Materials, it can exquisitely enrich the core value and quality of the product.

Dual Color Injection Molding Machine (DCV Series)

Categories : Horizontal Injection Molding Machines

• Effectively eliminating rotary inertia, adopting mechanical design for orientation and orienting turntable table by to-and-fro rotary. • With alternative rotary methods, machine is dual-purpose by operating with turntable table and spindle alternatively. Keeping a highly precision level in operation by adjusting turntable table with the accordance of its mold weight, to protect guide pins and ensure precision clamping orientation. • Effectively keeping a precision balance on mold to avoid table leaning forward, hold the mold stable without damaging guide pins.

YD Vertical Four-Column/Two-Color Rotary Table-Vertical Clamping and Vertical Injection Molding Machines

Categories : Vertical Injection Molding Machines

A. Standard double injection Vertical 4-columns direct-pressure clamping. In the upper mold plate, two separate vertical injection units is installed(separate injection hydraulic oil route) with the addition of round disc for this double injection machine. - Clamping force is 90- 500TON. Computerized and exclusively configured hydraulic system is used, which is more suitable for the production of general products( or special double-material) injection molding. - Two molds are installed on the upper mold plate while three lower molds are installed on the disc. When molding, the disc rotates alternatively at 120°to complete the two-color (two-material) injection molding or overmolding. - Highly efficient disc with water jacket device in the middle for cooling of the lower mold. - Expandable computer programs and special multistation disc (i.e. two upper molds and four lower molds). In the two lower modes, automated embedding and removing devices can be installed optionally to achieve automation of the whole machine work and increase production efficiency. B. Other double injection machine: - Type 1: A set of independent vertical “injection units” is added onto the upper mold plate of the original injection machine to form a double injection machine. Example: YH / YR / YC models + vertical injection. - Type 2: On the original injection machine, one or more sets of independent horizontal (level) injection units is combined to form a double injection machine. - Example: YH / YR models + horizontal injection - Type 3: The two-colors injection molding machine is combined to form a double injection machine by sharing a common disc. - Example: a. YH model + YT model + disc (2 ~ 4 stations) b. YH model + YH model + disc (2 ~ 4 stations)

Non-post Double Injection Machine - YL Series

Categories : Vertical Injection Molding Machines

Double color injection. Three-side open space makes removing and insert of automation equipment easier.

Mixing Color Injection Molding Machine 120BS to 300BS

Categories : Injection Molding Machines by Color

Several embedded injection processes on two barrels to inject two melts on different stages. Times or positions to create different layouts are found in molding parts.

Multi-Color Injection Molding Machine

Categories : Horizontal Injection Molding Machines

Tie-bar less and big rotary design gives more space for operation. The cable hanger set up in the center of the rotary and out of the molding area, avoids any danger when workers insert the cables into the molds, more safe and efficient for production.